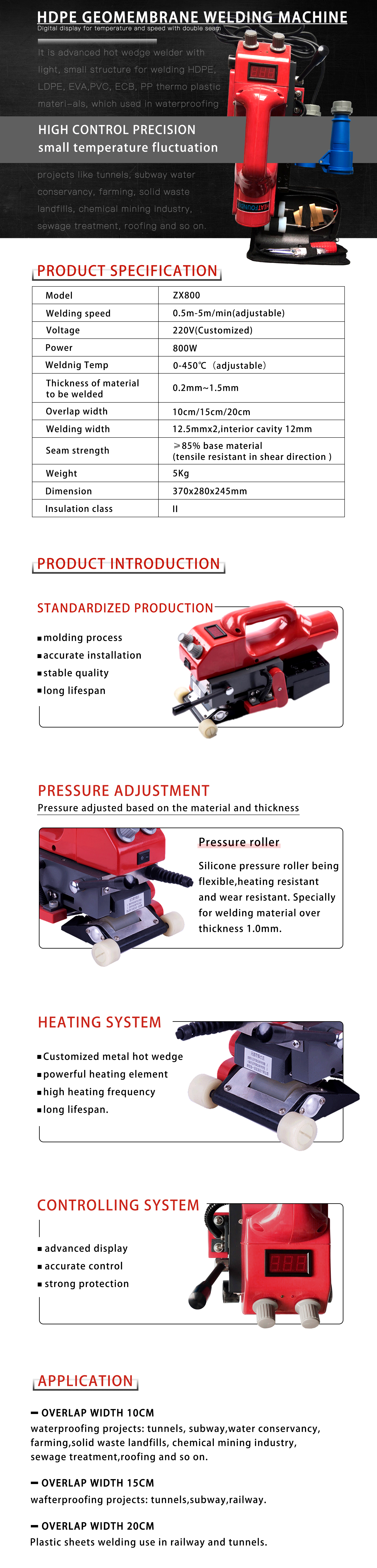

ZX800 HDPE Geomembrane Welding Machine

Specifications:

It is advanced hot wedge welder with light, small structure for welding HDPE, LDPE, EVA, PVC, ECB, PP thermo plastic materi-als, which used in waterproofing projects like tunnels, subway water conservancy, farming, solid waste landfills, chemical mining industry, sewage treatment, roofing and so on.

Scope of application:

This series of welding machine is a new generation of enhanced welding machine, which meets geomembrane and waterproof board.

The application needs in the field of modern waterproof engineering are widely used in highways, railways, tunnels, reservoirs, canals, sewage pools,

landfills, biogas digesters, artificial lakes, garage roofs, tailings, building anti-seepage and other waterproof projects.

Suitable for welding of hot melt materials such as PE, HDPE, LDPE, PVC, EVA, ECB, PP, PPR, drainage board, composite film, anti-seepage film, geomembrane, waterproof board, etc.

Features:

Circuit board application imported welding machine technology, computer input program, automatic constant temperature P control,

High control precision, small temperature fluctuation, speed control part adopts pulse width modulation (PWM) automatic voltage regulation and steady speed circuit,

DC servo motor drive, large output torque, stable walking, strong climbing, vertical crawling and road load change when maintaining speed Constant.