OEM/ODM Supplier 99% Alumina Ceramic Tube - Fireproof Ceramic Fiber Paper – Heatfounder

OEM/ODM Supplier 99% Alumina Ceramic Tube - Fireproof Ceramic Fiber Paper – Heatfounder Detail:

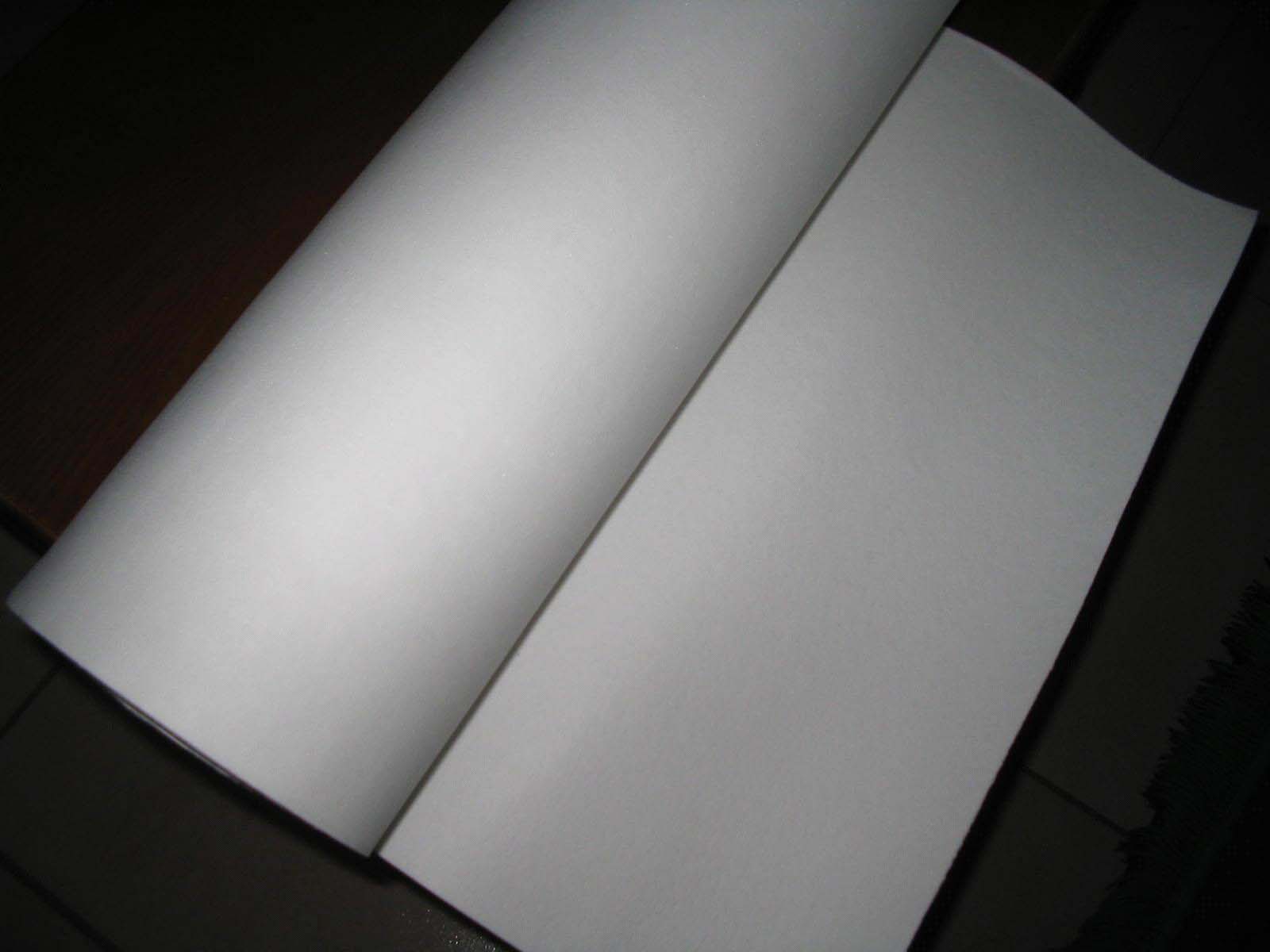

Ceramic Fiber Paper Composition, Properties and Applications

Production process:

Raw materials (fiber cotton) add water — pulping — agitation — paper forming — dry — coiling.

Features:

High-strength anti-tearing

High flexibility

Low slag content

Precise thickness

Smooth on both sides

Thermal shock resistance

Very low thermal conductivity

Application:

Iron and steel smelting continuous casting immersion nozzle insulation layer

Thermal expansion process glass industry

Glass ceramics and other building materials industry

Insulation short circuit

Insulation gasket

Expansion joint

Temperature control of processed parts during heat treatment

Punching slices on domestic hot facilities

Thermal resistance material in vehicles (muffler and exhaust)

Molten metal gasket

Fire prevention

Product description:

Ceramic fiber paper is produced from refractory fibers plus a small amount of organic binder.

It has excellent thermal insulation properties, can be handled by hand, and is convenient to construct.

Very flexible and resistant to tearing. Particularly suitable for deep processing. Such as: laminated structure, punched, curled or folded.

It is a chemically stable insulating material with a maximum temperature of 1260 ° C.

The organic binder can be completely burned out when heated for the first time, and the loss on ignition temperature is about 300 °C.

Main Performance Parameters

Type: Shgtzdh Ceramic Fiber Paper

Classification temperature: 1260 ° C, 1350 ° C

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for OEM/ODM Supplier 99% Alumina Ceramic Tube - Fireproof Ceramic Fiber Paper – Heatfounder, The product will supply to all over the world, such as: Cairo, St. Petersburg, Nicaragua, With the superior and exceptional service, we've been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.